Alluminium titanate

since 1982...

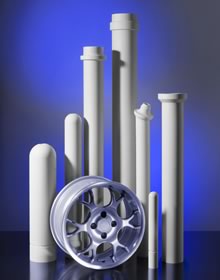

State-Of-The-Art Foundry Ceramics

The extreme conditions in the non ferrous metal processing world require specialised materials. Unlike ordinary and conventional materials, our range of materials (ATI, ALUTIT and Al2TiO5) is able to withstand extreme foundry conditions, such as:

heavy-duty operation, temperatures up to a maximum of 1000° and with temperature variations up to hundreds of degrees.

Aluminium titanate is famous for its non-wettability on contact with aluminium and considerable resistance to thermal shock.

ALUTIT is the ideal choice for Aluminium foundries; its outstanding resistance to chemical and abrasion also guarantees absolutely no “invasion” of the metal.

Aluminium Titanate is a versatile material tried and tested in the foundry

Aluminium Titanium is used for the manufacture of low pressure stalk tubes up to 1.75 metres long and furnace feeder pipes, as well as nozzles, rings and many other items.

Properties:

Excellent thermal shock resistance 0 – 1000

Very low thermal expansion (<1×10⁻⁶K⁻¹ between 20° and 600°)

Excellent thermal insulation (1.5 W/mK)

BLow Young’s modulus (17 to 20GPa)

Good chemical resistance

Low wettability on contact with the metal

Applications:

Rings for the continuous casting of brass

Uprights and inserts for dies and equipment

Furnace feeder pipes

Bushes and bush holders for dies and equipment

Insulating rings

Nozzles, sliding plates and stoppers

Low pressure stalk tubes

We are able to optimise individual requests to the customer’s specifications.

Request information about our products

The main aim as always been to supply products/machinery/technologies and consulting in order to satisfy all the requirements of the customers.